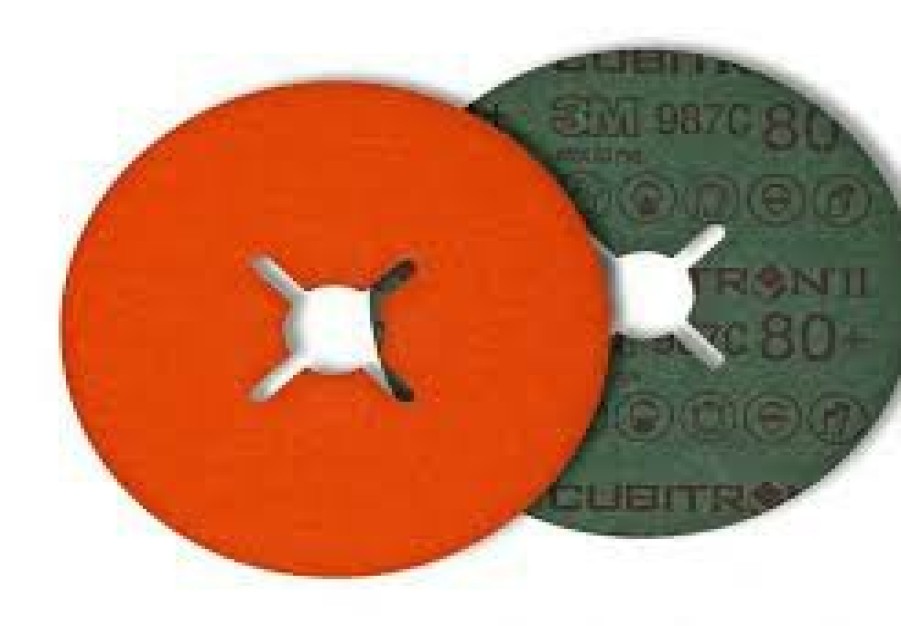

Cutting & Abrasives 3M Grinder Discs | 3M Cubitron Ii Fibre Disc 125 X 22Mm 987C 36G 25 Pack Stainless Steel

$149.99 $96.97

Cutting & Abrasives 3M Grinder Discs | 3M Cubitron Ii Fibre Disc 125 X 22Mm 987C 36G 25 Pack Stainless Steel

Details

3M™ Cubitron™ Ii Fibre Disc 987C Offers Significant Gains In Productivity On Medium To High Pressure Operations With Our Exceptionally High-Performing Ceramic 3M Precision- Shaped Grain Combined With Stiff Fiber Backing. Suitable For Use On Almost All Metals And Excels In Stainless Steel, Cobalt Chrome, And Nickel Alloy Applications.

This Disc Achieves A Higher Cut-Rate, Greater Durability, And Longer Life Than Other Fiber Discs—All With Less Grinding Pressure. 3M™ Cubitron™ Ii Fibre Disc 987C Is Ideal For Edge Chamfering, Beveling, And Removing Carbon Steel Welds, Mill Scale, Pits And Imperfections, Machining Grooves, And More. Super-Fast Cut With Less Pressure On All Metal Types . Because 3M Precision Shaped Grain Contributes To An Exceptionally High Cut-Rate With Less Pressure, Operators Can Finish Tough Tasks Faster And With Less Fatigue. A Heat-Activated Grinding Aid Incorporated On The Disc Makes This An Outstanding Product For All Types Of Metal—It Helps Keep The Disc Cooler On Stainless Steel And Heat-Sensitive Metals Such As Nickel Alloys And Titanium, Thereby Reducing Metal Discoloration/Oxidation And The Chance Of Heat-Related Stress Cracks. Moreover, Because The Abrasive Itself Stays Cooler And Sharper, 3M Precision Shaped Grain Discs Last Significantly Longer Than Conventional Ceramic Grain Discs, Delivering A Lower Cost Per Grind With Fewer Disc Changes. The Nitty Gritty . These Fiber Disc Have A Center Hole That Attaches To A 3M™ Disc Pad Face Plate And 3M™ Disc Hub, And Is Mounted On A Right Angle Grinder With A Compatible Disc Retainer Nut (All Sold Separately). 3M™ Cubitron™ Ii Products Have Raised The Bar For High-Performing Abrasives. 3M Precision Shaped Grain Outcuts And Outlasts Conventional Ceramic Industrial Abrasives And Requires Less Grinding Force To Achieve Superior Performance. The Result Is That Operators Can Grind Faster And Complete More Parts Per Disc With Less Muscle-Work And Fatigue. Experience The Powerful Performance Of 3M™ Cubitron™ Ii . To Create 3M Precision Shaped Grain, Our Engineers Started With 3M™ Ceramic Abrasive Grain And Used Proprietary Technology To Form The Grains Into Triangular Structures And Electrostatically Orient Them On The Backing To Form Sharp Peaks That Maximize Cutting Potential. These Peaks Slice Cleanly Through Metal Like A Knife Through Butter, Rather Than Gouging Or Plowing As Traditional Abrasives Do, And Continuously Self-Sharpen As The Points Break Off. This Generates A Super-Fast Cut And Lessens Heat Build-Up Due To Friction, Reducing Heat-Related Stress Cracks And Discoloration.3M Precision Shaped Grain Also Wears Evenly, And Because The Abrasive Itself Stays Cooler And Sharper, 3M™ Cubitron™ Ii Products Last Significantly Longer Than Their Conventional Ceramic Counterparts, Ensuring Extended High Performance In Production Applications. Fiber Discs — Ideal For Tough Grinding Applications . Fiber Discs Are Heavy-Duty Discs Ideal For Weld Removal, Grinding, And Blending Large And Small Areas Of Metal Surfaces. They Feature A Tough, Stiff Backing Made From Hardened Fibers That Resist Wear And Can Handle Tough Grinding Applications.

- 3M Precision Shaped Grain Maintains Super-Sharp Points That Cut Exceptionally Fast With Less Pressure

- Disc Life Is Significantly Longer, Completing More Parts Per Disc And Requiring Fewer Disc Changes

- Grinding Aid Incorporated On The Disc Minimizes Grinding Temperatures For Heat-Sensitive Alloys

- Stiff Fiber Backing And A Strong Resin Bond Provide Durability And Tear-Resistance For Heavyweight Applications Such As High-Pressure Weld Grinding

- Center Hole Mount Is Compatible With 3M™ Disc Pad Face Pates And Hubs, And Requires The Use Of A Disc Retainer Nut (All Sold Separately)

- Complete Stainless Steel Solution

Be the first to review “Cutting & Abrasives 3M Grinder Discs | 3M Cubitron Ii Fibre Disc 125 X 22Mm 987C 36G 25 Pack Stainless Steel” Cancel reply

Related products

Cutting & Abrasives

Cutting & Abrasives

Cutting & Abrasives

Cutting & Abrasives Anest Iwata Tools | Anest Iwata Aqua Dry Gun Paint Air Blower Spray Booth Dryer

Cutting & Abrasives

Reviews

There are no reviews yet.